542T transformer heavy haulaged by TIANDI 12x4 TJV4 Multi axle trailer

China TIANDI SPMT Commissioning

TIANDI's new TJV4 SPMT under commissioning in factory yard.

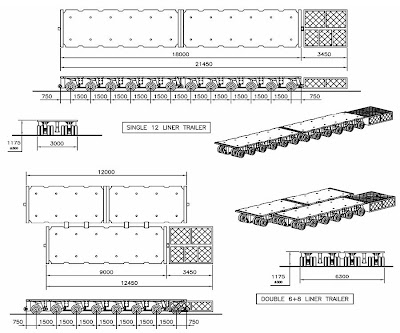

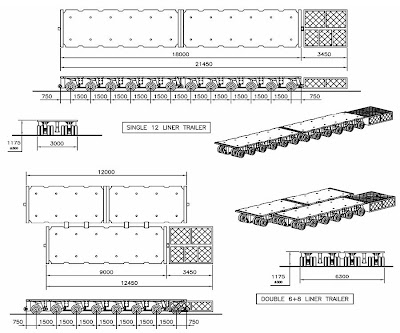

Here is a standard configuration of TJV4 SPMT

20 lines Self propelled modular trailer Main technical Specification:

| 1 Kerb weight(Kg) | 81800 |

| 2 Rated speed (Ground, full load)(Km/h) | 5 (PPU drive) |

| 3 Max. speed(empty load)(Km/h) | 10 (PPU drive) |

| 4 Max. Pulling force(N) | 480000 |

| 5 Platform measrurement(L×W×H)(mm) | 30980×2990×1070±300 |

| 6 Outer measurement(L×W×H)(mm) | 35875×2990×1070±300 |

| 7 Wheelbase(mm) | 1550 |

| 8 Tread(mm) | 1820/735 |

| 9 Approaching Angle/Departure Angle | 6°/6° |

| 10 First wheel Max. steering angle | 50° |

| 11 Drive axle | 6 |

| 12 Axle lines | 20 |

| 13 Tyre spec | 215/75R17.5 or 7.50R15 |

| 14 Rim spec. | 17.5×6.00 |

| 15 tyre number | 160 |

| 16 Syspension type | Hydraulic |

| 17 Engine power/speed | 375Kw/2000rpm |

| 18 Engine model | D2876LUE604 |

Technorati 标签: Spmt, Heavy Haulage, Heavy Lift, Abnormal Transport, Modular Trailer, Multi Axle,

China TIANDI SPMT Commissioning

TIANDI's new TJV4 SPMT under commissioning in factory yard.

Here is a standard configuration of TJV4 SPMT

20 lines Self propelled modular trailer Main technical Specification:

| 1 Kerb weight(Kg) | 81800 |

| 2 Rated speed (Ground, full load)(Km/h) | 5 (PPU drive) |

| 3 Max. speed(empty load)(Km/h) | 10 (PPU drive) |

| 4 Max. Pulling force(N) | 480000 |

| 5 Platform measrurement(L×W×H)(mm) | 30980×2990×1070±300 |

| 6 Outer measurement(L×W×H)(mm) | 35875×2990×1070±300 |

| 7 Wheelbase(mm) | 1550 |

| 8 Tread(mm) | 1820/735 |

| 9 Approaching Angle/Departure Angle | 6°/6° |

| 10 First wheel Max. steering angle | 50° |

| 11 Drive axle | 6 |

| 12 Axle lines | 20 |

| 13 Tyre spec | 215/75R17.5 or 7.50R15 |

| 14 Rim spec. | 17.5×6.00 |

| 15 tyre number | 160 |

| 16 Syspension type | Hydraulic |

| 17 Engine power/speed | 375Kw/2000rpm |

| 18 Engine model | D2876LUE604 |

Technorati 标签: Spmt, Heavy Haulage, Heavy Lift, Abnormal Transport, Modular Trailer, Multi Axle,

TIANDI lauches new hydraulic modular trailer

By remaining the great loading capacity (22.5ton @ 18km/h) as those previous models, TJV2's main upgrade features are as follows:

Smaller turning radius: The TJV2 trailer's first wheel steering angle has been upgraded from +/-50 degrees to +/-55 degrees.

Better passing through capacity: Platfrom height from 1080 +290/-310mm changed to 1080 +/-325mm, which makes the trailer has even better passing through capacity on rough road.

Easy connection: The pipe connecting system is moved to both side of the trailer, which is easier for piping line connection during module combination. Fast connectors helps to increase work efficiency and safty.

the one follow is TIANDI's regular TJV1 Hydraulic Modular trailer

(According to customer requirement, TJV1 can be adjust to combine with Nicolas MDE type and TJV2 can be adjust to couple with Nicolas MDED type from Europe.)

More detail features please feel free to contact tiandihi@gmail.com or msn with jefflee@live.com.

SCHEUERLE SPMT been tested before delivery for Australia Mining Company

Reported by Transportweekly 22.12.2008 (Pictures from BigLorryBlog)

SCHEUERLE received an order from the company Griffin Coal Mining in Perth, West Australia, to deliver heavy duty transport vehicles for transportation of huge excavators and dumpers, which are used in the coal mining industry. The machines, weighing up to 700 tons, put very special demands on the transporters. After about one year of development and construction the self-propelled transport system, which is based on the successful SCHEUERLE InterCombi series, has now been tested extensively before delivery.

Griffin Coal Mine is one of the biggest strip mining companies in Australia. Approx. 200 kilometres south-eastern of Perth, about 3 million tons of coal is mined annually. Already during the beginning of the Australian industrialisation, the Griffin Coal Mine played an important role by supplying to the national railway company. By now Griffin Coal Mine Company is one of the major subcontractors of the West-Australian energy sector, that operates several energy producing power plants with coal from the so-called „Colli Basins“.

If additional coal fields are to be made accessible to secure future energy supplies, massive excavators and dumpers also have to be relocated to this new site. However, a strip mining excavator, which can weigh up to 700 tons, is not designed for covering long distances. For this reason Griffin Coal Mine Company placed an order with SCHEUERLE to develop a powerful transport system.

SCHEUERLE SPMT been tested before delivery for Australia Mining Company

Reported by Transportweekly 22.12.2008 (Pictures from BigLorryBlog)

SCHEUERLE received an order from the company Griffin Coal Mining in Perth, West Australia, to deliver heavy duty transport vehicles for transportation of huge excavators and dumpers, which are used in the coal mining industry. The machines, weighing up to 700 tons, put very special demands on the transporters. After about one year of development and construction the self-propelled transport system, which is based on the successful SCHEUERLE InterCombi series, has now been tested extensively before delivery.

Griffin Coal Mine is one of the biggest strip mining companies in Australia. Approx. 200 kilometres south-eastern of Perth, about 3 million tons of coal is mined annually. Already during the beginning of the Australian industrialisation, the Griffin Coal Mine played an important role by supplying to the national railway company. By now Griffin Coal Mine Company is one of the major subcontractors of the West-Australian energy sector, that operates several energy producing power plants with coal from the so-called „Colli Basins“.

If additional coal fields are to be made accessible to secure future energy supplies, massive excavators and dumpers also have to be relocated to this new site. However, a strip mining excavator, which can weigh up to 700 tons, is not designed for covering long distances. For this reason Griffin Coal Mine Company placed an order with SCHEUERLE to develop a powerful transport system.

Mammoet buys 650 modular trailer axle lines

The order, placed in 2007, includes some power packs. It will be delivered in 2008 and 2009, Mammoet said.

Mammoet will use the extra lines to expand the fleet, and is not planning to use them for any particular job.

It will receive 592 lines from Scheuerle and 50 from Kamag, said Bernd Schwengsbier, president of parent company Transporter Industry International sales. TII convinced Mammoet to switch 50 lines to Kamag because of production bottlenecks at Scheuerle.

He said that Scheuerle has a two-year waiting list for new SPMTs, despite having tripled capacity to more than 1,200 lines per year.

Fabricators can save money by assembling larger and larger units. Last year, Sarens' Norwegian subsidiary Transrig assembled 452 SPMT axle lines to lift a single 10,000t offshore platform topsides.

25 April 2008

Fm: http://www.cranestodaymagazine.com/story.asp?storycode=2049478

SPMT - Self Propelled Modular Transporter

SPMTs are increasingly used in the construction and oil industries, and have been recently begun to be used to replace bridge spans, in the United States and Europe, and more recently, Canada.

A typical SPMT can have a grid of several dozen computer-controlled wheels, all individually controllable and steerable, in order to evenly distribute weight and steer accurately. Each individual wheel can swivel independently from other wheels, to allow the SPMT to turn, move sideways, or even spin in place. Some SPMTs allow each wheel to telescope independently of each other, so that the load can be kept flat and evenly distributed while moving over uneven terrain. As SPMTs often carry the world's heaviest loads on wheeled vehicles, they are very slow vehicles, often moving at under one mile per hour while fully loaded. Some SPMTs are controlled by a worker with a hand held control panel, while other SPMTs have a driver cabin. In addition, multiple SPMTs can be combined to transport massive building-sized objects.

SPMTs have also been featured on Discovery Channel during shows involving engineering.

Normal load/axle-line: 22.5tons or 32.5tons.

Drive type: Hydrostatics

Steering type: Normal linkage steering (first wheel max. steering angle 55-60degree) or independant steering (also called e-multi steering. all wheels +/- 115 to 135degree or even 360degree steering).

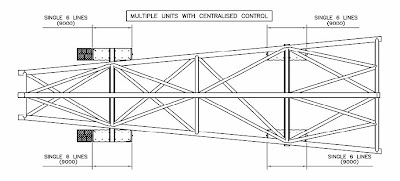

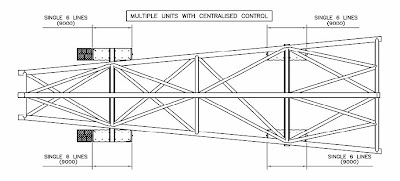

Different Combination Mode of SPMT

Multiple combination with central remote control

SPMT - Self Propelled Modular Transporter

SPMTs are increasingly used in the construction and oil industries, and have been recently begun to be used to replace bridge spans, in the United States and Europe, and more recently, Canada.

A typical SPMT can have a grid of several dozen computer-controlled wheels, all individually controllable and steerable, in order to evenly distribute weight and steer accurately. Each individual wheel can swivel independently from other wheels, to allow the SPMT to turn, move sideways, or even spin in place. Some SPMTs allow each wheel to telescope independently of each other, so that the load can be kept flat and evenly distributed while moving over uneven terrain. As SPMTs often carry the world's heaviest loads on wheeled vehicles, they are very slow vehicles, often moving at under one mile per hour while fully loaded. Some SPMTs are controlled by a worker with a hand held control panel, while other SPMTs have a driver cabin. In addition, multiple SPMTs can be combined to transport massive building-sized objects.

SPMTs have also been featured on Discovery Channel during shows involving engineering.

Normal load/axle-line: 22.5tons or 32.5tons.

Drive type: Hydrostatics

Steering type: Normal linkage steering (first wheel max. steering angle 55-60degree) or independant steering (also called e-multi steering. all wheels +/- 115 to 135degree or even 360degree steering).

Different Combination Mode of SPMT

Multiple combination with central remote control